Meat aged under controlled conditions in Switzerland for 12 weeks using the patented improved fungus. Can mould-covered meat be safe?

Manuel Kälin, as a food lover and a member of the management board of Luma Delikatessen, is guiding the company to different fields, doing product research and setting new meat trends. Luma Delikatessen is the brainchild of long-time friends Lucas Oechslin and Marco Tessaro. These young entrepreneurs age fresh meat using a special mould culture to create top quality products.

Tradition and biotechnology

The secret of Luma lies in a combination of traditional methods with the latest biotechnology. This is slow maturing of meat and a natural refining by mould. This gives these extraordinary cuts of meat their distinctive aroma and unique taste. As an international patent holder Luma got connected worldwide and in just a few short years, their passion for meat has become an emblem of high-quality food.

What is Luma?

Luma is special, high-quality meat. As Manuel said, it is beef, pork and veal which they were maturing in their rooms under the right conditions. Luma is also some kind of Swiss innovation. Modern biotechnology has allowed them to produce a product on a new standard and the higher level of meat.

The beginning of mould aged meat

This controversial way of preparing meat immediately met with a positive response. Eston Blumenthal was one of the first, who visited production of mould aged meat in 2014-15. He had checked out their lab and production. As Manuel said, “He was kind of excited to have a new possibility, new taste that he could bring back in the kitchen and create amazing dishes.” In turn, Andre Jäger said that this could be a new dimension of quality.

How does the mould work here?

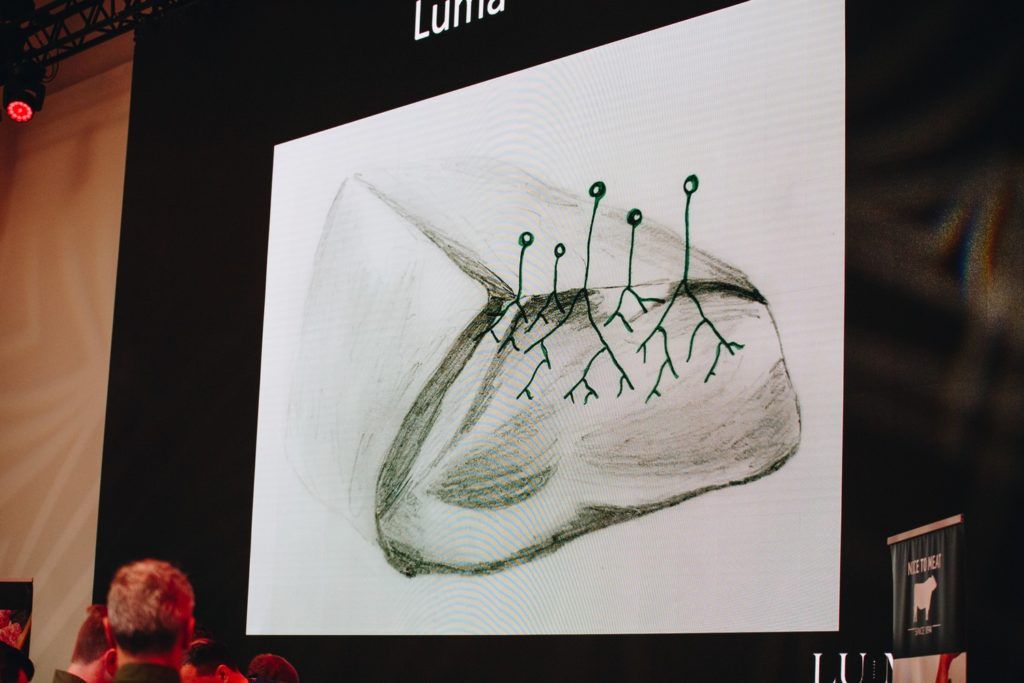

“Meat is nothing else than just skeletal muscle”, Manuel began to explain. The most important part in this process is connecting tissues. Connecting tissues are all around the muscle system. Manuel also explained what sarcomeres are – the smallest functional units in the system. They are filaments of myosin and actin. For the mould, thanks to these elements, meat is an excellent source of nutrition. In return, it brings its natural enzymes into the meat. In doing so, it changes the aroma profile and also the texture of the meat.

Mould aged meat – Proteolysis

Manuel explained to us what happens in this process.

“Proteolysis is just breaking off the proteins. As we know, collagen is also a protein. So, we just break down this ‘huge building’ by using enzymes. We make small cuts in different places and then the whole structure becomes a little more flexible and tender at the end.”

After ripening, the mould layer is cut away and the meat is vacuum sealed and frozen to -60 degrees Celsius so that the ripening process does not continue. Because the meat has lost a lot of moisture, there is no freezing damage to the cell structure.

Food safety

Some may fear this method of meat production and the mould used, but Manuel explains that the whole process is natural and safe.

“We use mould naturally occurring in our environment. Firstly, it is isolated and then introduced into our master cell bank. It is stored with liquid nitrogen at -200 degrees to keep the DNA stable. Then, from there it is transferred to the meat. This is the only way to ensure that the mould is always the same as DNA and changes the meat the same way.”

What’s more, Manuel added, this mould could even protect the meat.

“Our mould strongly suppresses unwanted flora, which means other bacteria or moulds don’t have a big chance to grow on that because we are doing that in a really high concentration solution.”

If you want to know more details about mould aged meat, check this video out:

Check out the interview with Bernd Breiter and Matthias Maurer: https://thebestchefawards.com/2021/11/05/kitchen-in-space-bernd-breiter-and-matthias-maurer/